Equipment May Be the Number One Key to Profitability.

Business success and profitability today, requires companies to do more with less. It’s no surprise that having an edge on the competition means you need to work faster and waste less. The best way to do that… Faster equipment, and a motivated/well trained crew!

Equipment’s Impact on Profitability

Many contractors start out with smaller equipment that’s more affordable. But, as they grow, this entry-level equipment can rob them of the profit they need to survive.

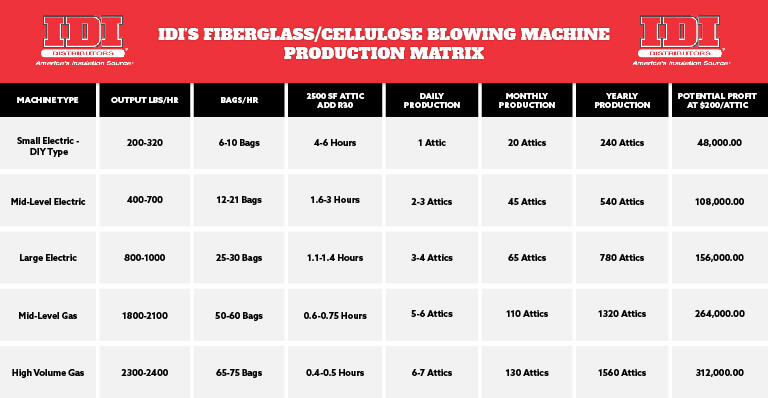

As an example, let’s look at how much fiberglass one crew can install, over a year, based on the level of equipment they are using. In this example, company A, B, and C, have their machines running the same amount of hours, and each job nets the company $200 in profit per attic. How much difference does a machine make? Prepare to be surprised.

Estimates are based on adding or installing R-30 into a 2500 sq ft. attic. While the chart in this post is based on fiberglass, the same analogy applies to spray foam equipment. All numbers are based on one crew, over one year, and the number of jobs completed based on the tools they are given.

Production rates in this chart are based on claimed rates of output. Manufacturers rates are based on wide-open blowing which is NOT recommended. Actual rates to achieve proper bag coverage would be 75-80% of numbers shown in the charts. For example, the IDI 18E can push 700 lbs/hr, (21 bags/hour) but a number of 18 bags/hour would be better used because this number is when the slide gate is at 75-80% (in order to give the machine time properly break up the material.) Additionally, some machines are tested with only 50’ of hose in order to show higher numbers. These machines’ rates have already been adjusted to reported rates from the field. The number of attics/days also reflects some driving, setup, and tear-down time.

Company A

Equipment

Company A starts the year with a “free” or entry level machine.

Performance

This machine can blow 6-10 bags an hour. Once the machine has been used for a few months, that number will likely drop to 6-8. All things considered, this crew could be counted on for one job a day or 20 per month.

Profits for the Year

This would give company A 240 jobs a year or a potential of $48,000 in profit based on the equipment they’re working with.

Company B

Equipment

Company B uses a mid-level electric machine for the year.

Performance

The machine’s production rate allows this crew enough time to do 2-3 attics a day.

Profits for the Year:

At the minimum, company B’s crew could insulate 2.25 attics per day resulting in a potential profit of $108,000.00 per year.

Company C

Equipment

Company C uses a mid-level gas machine for the year.

Performance

The machine’s production rate allows this crew to perform 3-4 attics per day which equates to about 1320 attics a year.

Profits for the Year:

At the minimum, company C’s crew could insulate 3.25 attics per day resulting in a potential profit of $264,000 per year.

The Winner? Company C!

Company C, with their mid-level gas machine, earned much more while using the same amount of labor as company A and company B. We don’t even need to look at the biggest gas machine. A mid-level gas machine offers over 5 times the production rate. In today’s tight labor market, that may be the golden ticket to boosting your profits.

Equipment’s Impact on Your Crew

Speaking of a tight labor market, is your equipment affecting your employee retention? Labor is the highest cost for most contractors, therefore, your crew’s production rates, their attitude, and liking their tools, are vitally important. The more you get out of each crew member, the greater your ability to compete in the marketplace. And, offering a wage high enough to convince people to work for you can be scary. But with slow equipment, it can be a waste of money.

In the example above, company A’s crew may be spending up to six continuous hours just blowing insulation into one attic. Consider the working conditions. That attic might be over 100 degrees or under 20 degrees. Either way … it’s not fun.

On the other hand, company C’s crew is in the attic for an hour or less, packing up and getting into a comfortable truck with AC or heat. Better yet, they are on their way to make you, and them, more money. Which crew is happier? Which crew has better employee retention?

Yes, crew members like working with good equipment — after all, no one hates good tools! Some workers would even consider a job change to work for a contractor with higher-quality equipment. Don’t you want your crew to feel motivated to get more jobs done per day?

Better Equipment Means More Business

No doubt, profitability is directly affected by your equipment. Good equipment can get you off the job faster and help you satisfy more customers. The best ROI for your business is quality equipment with high production rates. What’s your equipment like? Is it giving you the ability you need to compete in the market? Is it performing as well as it could be?

Get equipment that helps you increase yield and helps your crew work efficiently. See how the 2800-G improves your crew’s efficiency and your ROI! Don’t let old or entry-level equipment hold you or your crew back.

The end of the year is coming quickly. For those of you considering the tax advantages of buying equipment, contact your local IDI to see how you could be saving by purchasing new equipment this year! We are here to help grow your business and look forward to doing it every day.

Equipment used in these examples is averaged by category and based on 5 of the largest manufacturer’s published data. Published rates were then adjusted to reflect the rates that would allow for proper bag coverage.