I cannot tell you how many times I have been asked that question over the years.

Whether you call it a conditioned attic, a spray foamed attic, a closed attic assembly, or spray foaming a roof deck, the short answer is yes. I would do it 100% of the time, and I believe there are very compelling reasons why.

First off, closing the attic has loads of benefits when there is ductwork or mechanical (HVAC) within the attic space. (We’ll dive further into the science of this in a future blog.) The main goal of closing an attic is moving the mechanical into the building envelope (AKA conditioned space). So naturally, anything in the attic that used to reside outside the home, will now be inside the home. By closing the attic, we are taking the old insulation along with anything in it and moving it to the inside where it can be smelled throughout the home. Knowing this…

Reason #1: Unwanted Smells or Odors.

It’s not just what’s in the insulation that could make it smell. Certainly, any old friends like mice, bugs, bug bombs, pesticides, or squirrels, would provide plenty of unpleasant odors, especially as we bring them into an area that will likely have the highest humidity in the home.

Additionally, most consumers don’t realize that during the process of spraying foam, the attic gets filled with what are called amines, and normally these don’t smell good. Depending on the product used, there are times the processing of installing spray foam can smell more like a litter box. Ventilating during the spray process does a lot to remove these amines from the attic, but why take chances and allow the old insulation to absorb anything that may cause it to smell? And if we are honest, some are hard to ventilate while spraying and even some contractors who fail to ventilate while spraying.

As a contractor, when you get asked “do we have to remove the old insulation?”, a good response is: “As long as we are in control of all the factors that would cause the attic to smell, meaning ventilating 24 hours, turning off the HVAC, no one on the project while we are spraying, and removing the old insulation, we will gladly write you a guarantee that it will not smell. However, if we are not in control of all the factors that would make it smell, then we cannot be in control of the results. Is that fair?” The answer to this is almost always yes and normally results in a removal of the old insulation.

Reason #2: Getting a Good Air Seal.

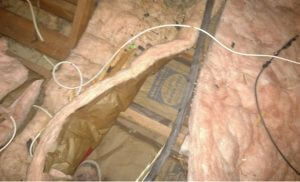

When it comes to attics, crawl spaces, or any other location on a building, they are either inside or outside of the building envelope/conditioned space. If they are not being conditioned, then they need to be well ventilated to prevent unwanted things from occurring (Like condensation or moisture build-up). Look at these attics with the old insulation left behind. Do you think they got a good air seal?

How big of a deal is it? Well, first off almost every building has leaky ductwork. Old ones often leak a lot. In new construction, they are allowed 3-4% depending on what you are testing. In older systems, the numbers can be over 20%. Now, imagine an attic in Houston or Florida that is spray foamed, but when you add up the little cavities or unsealed areas, it has about two inches of gaps or holes that were missed. If the return for the HVAC leaks, (Normally it does) then it will cause the attic to suck or be negatively pressured. This then causes the system to draw warm humid air through these holes. As this air cools down, it can no longer hold as much moisture. This forces the moisture in the air to find surfaces to condense on and deposits moisture or water into the space where it can start to grow things (and smell). Engineers studied buildings in central Florida with similar holes that, over the course of a year, brought in and deposited over 200 gallons of water. Now we’re not saying where you live has the same issues as Houston or Florida. What we are saying, is that getting a good air seal is critical and requires that the old insulation be cleaned away from every area where spray foam insulation is to be applied. That said, if you need to remove it from everywhere being sprayed, you might as well remove it all. It makes the job easier and you are taking fewer chances.

In the North…

The last thing you want in the north is for your spray foam to become a condensing surface. This happens when the face of the foam gets cold enough for moisture to form on it. In colder climates, a conditioned attic is warmed in the winter by heat migrating up from the space below. Sometimes they are called semi-conditioned because there is not an open HVAC supply run directly conditioning the space. Any holes or gaps in the insulation may allow cold air into the attic. When old insulation is left in place, not only might it smell, but it may prevent enough heat from rising, leaving the surface of the foam cold enough to allow for condensation. The photo below not only shows the old insulation but there’s a vapor retarder in the middle, making each of these problems worse.

In summary, closing an attic and moving your mechanical into a conditioned space is a great idea. On the other hand, leaving the old insulation in place while doing it is a bad one. For our IDI contractors, we hope this blog helps when you talk to customers about best practices.

Homeowners, GC’s, and Builders: IDI trains more contractors than anyone in our industry. Our trainings on building science, spray foam, healthy homes, and proper installation of the products we carry, has provided IDI with a network of the best insulation and building performance contractors. If you’re looking for more information on insulation, fiberglass, spray foam, or help with your air sealing or insulation project, we would gladly connect you to one of them in your area.

Duct Leakage Criteria (In the code since 2009) If the test is done on the “rough-in” stage of the HVAC installation, total duct leakage cannot exceed a 3% leakage rate or 3 CFM per 100 square feet of conditioned floor area. If an air handler is included in the “rough-in” leakage test, the total air leakage cannot exceed 4 CFM per 100 square feet of conditioned area (4% leakage).