Blowing Machine Component Maintenance

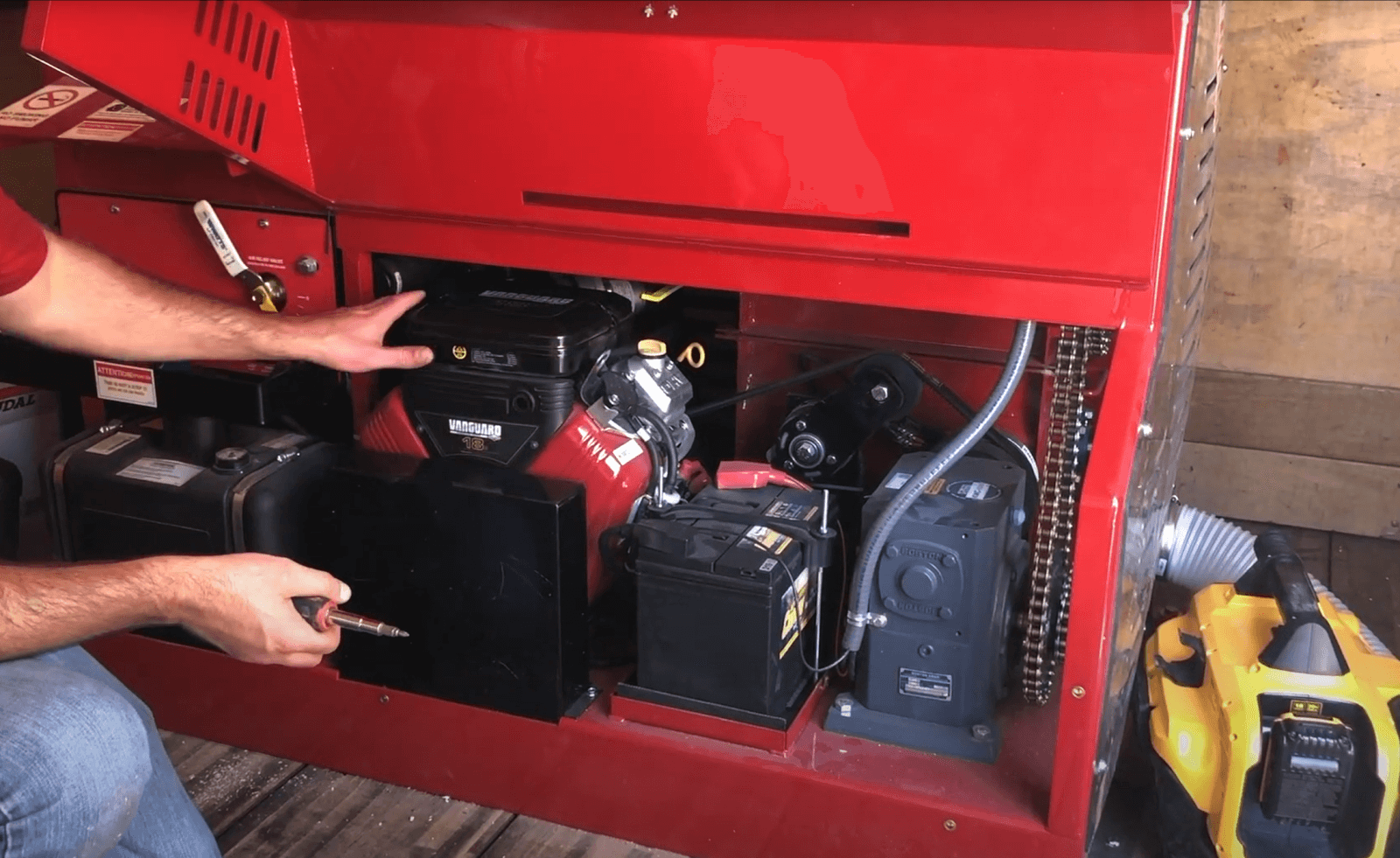

If you have a gas- or diesel-powered machine, daily engine maintenance includes checking fluid levels before starting work. It also means checking your maintenance schedule and making sure to get in oil changes, seals, and bearings when needed.

Not sure when maintenance should be done? Keep in mind this is a rough guide for maintenance of critical parts, but be sure to consult your schedule for more specific information.

- Gas engines require oil changes about once a year or every 100 hours.

- Gas, diesel or PTO machine blower pumps need to be greased every 80 hours.

- Grease machine agitator bearings every three months.

- Lubricate chains when you grease bearings, but use a dry lubricant — options like WD40 or grease will cause insulation buildup.

If you have a machine that is giving you issues beyond daily maintenance or if you’re looking to upgrade your insulation blowing machine, IDI is here to help. Get in touch or check out the equipment we have available today!

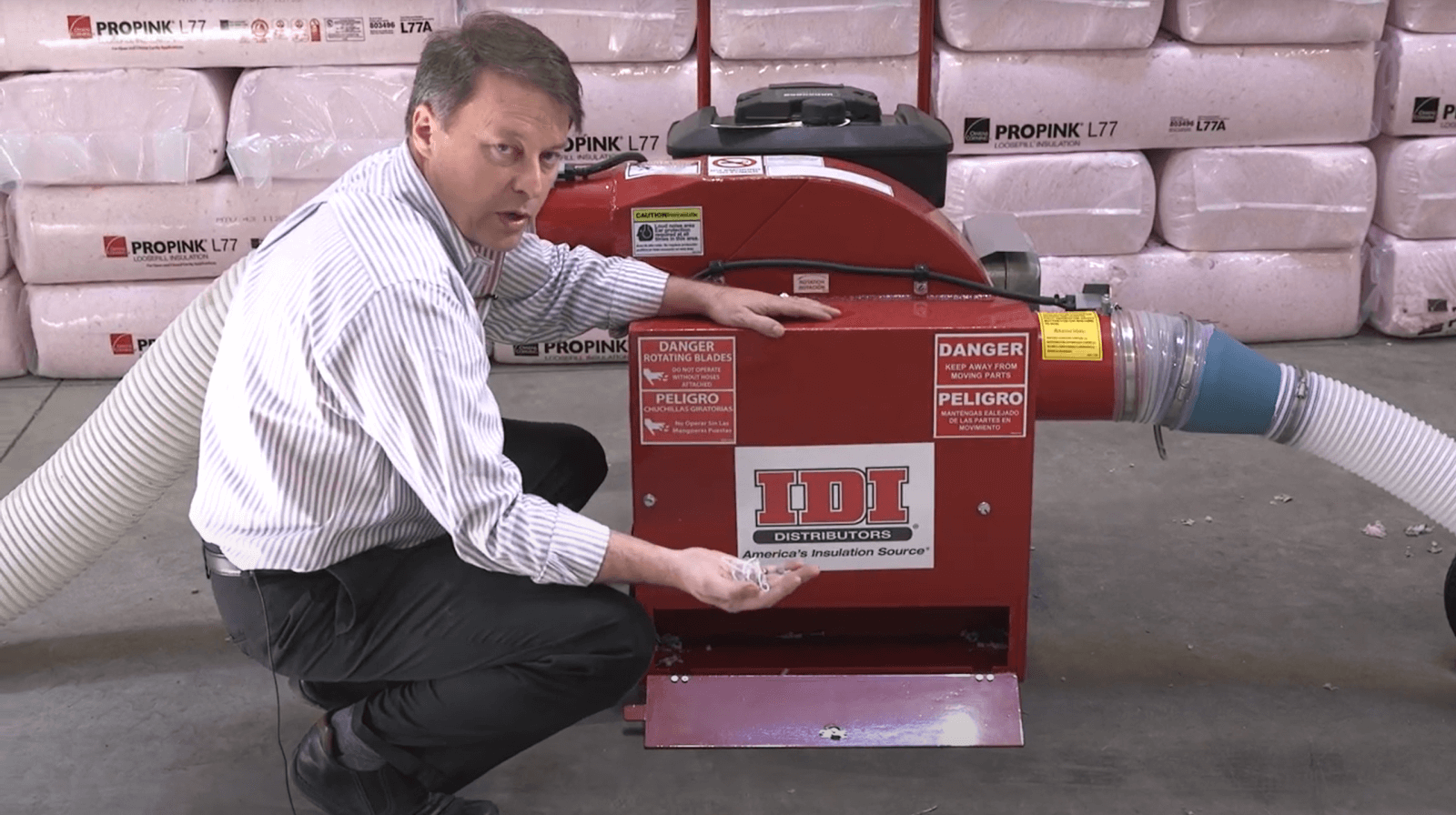

Clean Off Insulation Fibers & Debris

Anyone who blows insulation has seen all the dust and fibers that build up on the machine. The problem with this is, insulation insulates. Whether it’s blown in an attic or stuck to your machine parts, insulation will hold the heat in. Too much of this insulation buildup will cause the components on the machine to operate at a higher temperature than they normally would, resulting in premature wear and reduced life of parts. Clean the machine daily to keep it cool. This can be done with an air compressor or by simply emptying your blowing hose and using air only on the machine to blow off the insulation. Also, make sure to clean the blower filter before each job.

Insulation Removal Vacuums

When working on insulation removal vacuums, most of the service needed will be on the engine. As with gas blowing machines, make sure to check engine fluid levels before operating the vacuum and clean the engine daily. If cleaning isn’t completed often or thoroughly enough, the insulation can build up on the cooling fins in the engine and cause overheating. If you have any issues with the engine while in the warranty period, any insulation buildup on the engine could void the warranty.

If you’re looking for additional assistance with your insulation removal vacuum or want to find a new piece of equipment for your business, contact us or browse our selection of insulation vacuums.

Keep Your Machine Running at its Best

Machine maintenance is an easy way to keep your equipment and business operating at a high level. Equipment breakdown not only creates stress in making sure jobs get done, it also creates cascading problems for you as a business owner that anyone would rather avoid. If you want to make sure your business and machines are performing as well as possible, check out our maintenance sheets[1] for insulation blowing machines, as well as removal vacuums.

For more information on maintenance schedules, equipment, or any of the products we sell, reach out to your local branch or anyone at IDI, where we look forward to earning your business every day.

Is there a preferred link we can use here? I’ve not found a centralized spot for maintenance sheets on the IDI site.