A large portion of the customer satisfaction and safety issues related to Spray Foam Insulation are rooted in the failure to properly ventilate during and after the installation. The amines and other chemicals introduced during the process are much harder to remove after the application. The easiest way to avoid problems in the first place is having good fans, setting them up properly, and using them. But what makes a good fan and how should they be set up?

They should have sensors to prevent them from overheating. Some are also explosion-proof because you never know when your crew is going to try and remove gas or toxic air from a confined space or other areas. These Class 1 Division 1 fans are almost double the price, but the price is not a consideration if you need them. The most popular fans for ventilating during a spray foam application are the axial fans with canister ducting. As an example, Allegro offers them in sizes ranging from 8”-16” and 1200-3200 cfm.

Another great ventilation item is the Manhole Ventilation Passthrough (MVP) This works great when you are taking more than one duct through an attic access.

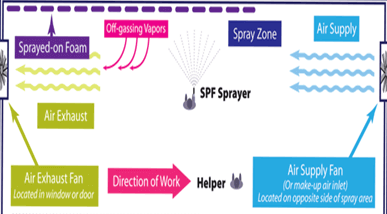

The biggest factor though is planning out your ventilation. The best setup is to create negative pressure by having two fans going out on one side of the area and one fan bringing air in on the opposite side. This allows you to start spraying near the exhaust and work toward the fresh air coming in and keeps the sprayer out of the path where the highest concentration of chemicals are being exhausted.

A BIG note of caution here is that spray foam particles will stick to, collect on, and ruin your nice fan. Be sure to place some sort of filter over the duct to collect them before they get in. This can be as simple as cutting two discs 1” larger than your duct and pushing them into the duct where the air comes in. The easiest to use seems to be the inexpensive blue spun polyester filer that comes in rolls and can be purchased at most lumber and hardware dealers.

So remember, it all starts with a good fan. There are a lot of those, but we do like the allegro for a few reasons.

- Smallest profile in the industry (9533)

- Only 16” blower system with built-in storage canister and Duct (9553 series)

- Overheat sensor with automatic shut off

- Blowers available from 8” to 16”

- Blowers that can be used with multiple power sources (AC, DC, Gasoline, Air)

So, if you need a good fan, be sure to check out this month’s featured products. If you have more questions on these fans or any of IDI’s products, reach out to your local branch or any of us at IDI so we can help you keep your team safe and your company growing profitably