Good people are hard to come by. Without them, maintaining a thriving business is almost impossible. No doubt many of you would love to go keep your crews healthy and injury-free year-round — but this is construction. Protecting your people and your profit becomes increasingly difficult when you add snow, ice, and sub-zero temperatures to the mix. With new guys on ladders and unpredictable roads, it’s important to always get your team prepared for the worst.

While there is no way to prevent everything that may happen in the coming year, IDI would like to help your team make this winter a productive and safe one. Our goal is to help you protect your people, yourself, and your profit this year with these 7 winter construction safety tips and best practices.

1. Winter Driving

One of the most challenging aspects of working in the winter is driving. Many have mastered driving winter roads in a can or pickup, but what about a work truck? When they are empty the back end has no traction and when full they can dig deep ruts, and then there is the challenge of pulling a trailer on ice …

While most of us have had to get our own vehicles back on the road after a slide, your team has a truck equipped with everything your business needs to succeed — that’s a big responsibility.

Keep your expensive equipment safe by:

- Requiring your drivers to take a defensive driving course. These often result in a discount on your insurance and may help in a scary situation.

- Checking all vehicles for good treads on tires.

- Making sure you have full-size spare tires for emergencies.

- Keeping extra windshield washer fluid on hand and making sure to switch all vehicles over to the low-temperature blend.

- For many, chains should be on the truck, others could get back on the road by keeping a shovel and a bag of sand on hand.

2. Heating Cold Buildings

No one wants to work in a freezing building or cold outdoor site. Production rates go down, the chance for injury goes up, and the slightest miss of a hammer stings ten times as much. This means it’s time to bust out the heaters. Since turning on a building’s heating system isn’t always an option and electric heaters don’t produce enough warmth, the first choice for heating is usually an open flame fossil fuel burning unit.

As your team gets to work, keep these tips in mind:

- Without ventilation, carbon monoxide will build up inside. Before equipping a truck with a portable gas-fired heater, train employees on CO safety and have them sign off on a jobsite ventilation policy.

- Never have an open flame unit when operating spraying foam. Overspray, mists or fine particulates may be burned in the flames and produce toxic fumes.

- Be aware of snow loads and ice that could be warmed and dislodged while heating the structure.

- Keep heaters away from combustibles and any other fuel sources and do not attempt to dry clothes or other items on or near the heater.

3. Ice Melt & Snow Removal

Proper ice and snow removal is pertinent to winter construction safety not just on-site but at your office or warehouse as well. Not only could one of your staff slip and fall, but so could your clients or others visiting your location.

Follow these snow removal tips for your office and job sites:

- It may seem obvious, but bags of salt can be your best friend in the winter. Keep them on every truck and close by your loading areas.

- Never run out of salt or ice melt. Shop for it in the warmer months to stock up and avoid running out when you need it most (like a surprise November storm!).

- Make the job easy on yourself by buying nice shovels. You’ll get far more volunteers to shovel with an easy to use one as opposed to the cheap aluminum shovel that barely does the job.

4. Hypothermia & Frostbite

For whatever reason, people can become hyper-focused and not realize the effects temperature may be having on their bodies. Train your workers to dress appropriately, know the signs, and watch out for each other.

How Hypothermia occurs:

Hypothermia occurs when your body’s core temperature gets too low. One factor that increases the speed at which this happens is moisture. Quite often, insulators will be dressed in layers, working in parts of a warm building. They can begin to sweat and then find themselves working outside in the truck in much colder temperatures. Your body cools down as sweat dries, so ensure you and your workers are dressed in the appropriate amount of layers to prevent you from cooling down too much. You can also keep blankets, towels, and spare dry clothing on hand.

Signs of hypothermia:

Clumsiness, shortness of breath, shivering, sudden fatigue.

What to do?

Call 911, get affected person to heated area, remove any wet garments and wrap them in a dry blanket.

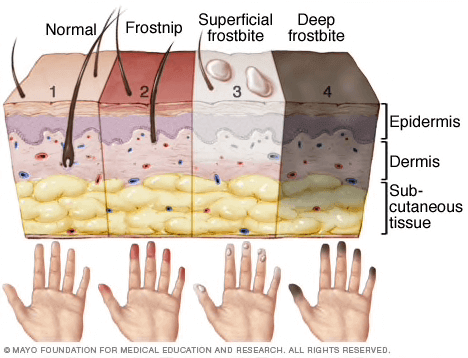

How Frostbite Occurs:

It’s most common on your extremities such as ears, toes, fingers, and nose. When parts of your body get too cold for an extended period, they will suddenly lose feeling and can begin to change color over a short period of time. Staying hydrated actually helps, so ensure you have extra water on hand for every member on your team.

There are three levels of frostbite.

- Frostnip

- Superficial

- Deep or severe

Review examples and treatments with your team so they know what to watch out for!

5. Keep Equipment & Tools Warm

When hoses or equipment break, the results can be hazardous and expensive. Wires, hoses, belts, and lubricants can all be affected by temperature.

Review our winter equipment safety tips and recommendations:

- To avoid cold hoses and brittle belts, keep them warm or let them warm up properly to avoid unnecessary stress on them.

- Keep your team on schedule by creating proper storage for expensive equipment both on your truck and in your warehouse. If you can, keep your trucks inside.

To help your team stay prepared all year round, IDI keeps winter concerns in mind when we create custom spray foam rigs for our customers! If your trailer or truck is not insulated, make sure your next one is.

6. Require the Right Clothing for Your Area

It’s your company, your jobsite, and your insurance, so make sure when it comes to proper winter attire your employees are prepared.

Follow these cold weather safety tips for outdoor workers and job sites:

- Brief your team about proper cold weather wear each year before the cold kicks in.

- Set the bar to a safe standard and hold your team to it.

- Keep extra jackets, hats and gloves available in your rigs in case of emergencies.

- Avoid cotton and goose down which can hold in more moisture and increase threats of hypothermia.

7. Be a Weather Geek

Make it part of your daily routine to check the weather in the morning so you can always keep your team updated and let them know you’re watching out for them.

Tips to live by:

- Follow the weather and share it with your team.

- Download a weather app and set up snow/storm notifications.

Certainly, most of these tips are things you and your crew are already doing, but it’s always good to train and retrain your staff. At IDI, we’re here to help you keep safety at the front of you and your employees’ minds. Contact us with any of your cold weather or insulation questions to keep your business running smoothly no matter the season!

May your business thrive, and may we continue to be one of your premier partners as we work to earn your business every day.