Upselling with Tech and Time

Sometimes all it takes to grow a project is testing, technology that shows proof of a problem and a few minutes of teaching a customer. The trio of testing, teaching and proof make it much more likely that you successfully close or increase the size of the job.

Take, for example, this experience of how some infrared imagery and a bit of well-explained building science helped expand a project and dramatically improve the insulation performance of a family home.

The job started small. The customer didn’t want to spend much, just moving insulation and air sealing the areas that were accessible at a single story 3/2/2 home — no vacuuming out the attic, no spray foaming the rim joist.

During the course of setting up the blower door and having a conversation with the homeowners, it became clear that while costs were a consideration, there was also an understandable lack of knowledge about building science and what the services they turned down could do for their home.

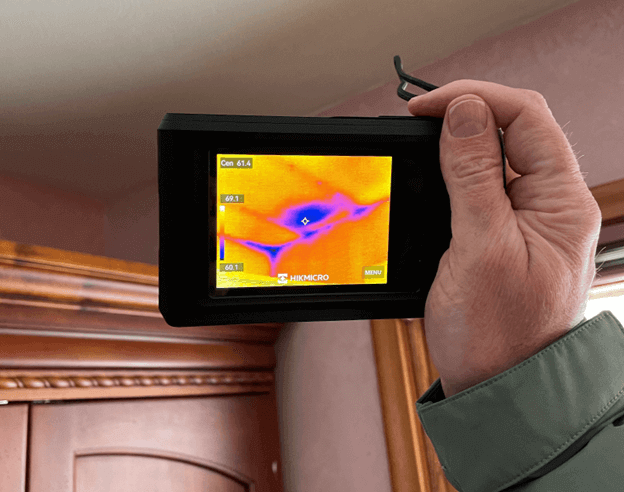

After the blower door ran for about 10 minutes, it was time for a walk through of the home. One of the homeowners joined to see what would get turned up in real time. Starting in the living room, the first infrared infrared images taken were of the ceiling. The homeowner asked what the purple on the picture meant — cold outside air being drawn into the home. Beyond air infiltration, this leakage brought in moisture and contaminants.

Naturally, the homeowner wanted to learn how to eliminate the leakage and block off the contaminant pathways. The home had a low slope roof, so the only real solution was to vacuum out the space, wedge a baffle in each bay and foam them in place. He agreed, if that was the best solution, that’s what should be done.

Down in the basement, there was a whistling window that a bit of caulk would fix easily. The big problem was the rim joist that the customers had decided against spray foaming. However, the sight of glowing purples and reds showing the leakage was all the homeowner needed to add insulating the rim joist to the project.

Having the right technology onsite made all the difference in the growth of this project. Sam Rashkin of the Department of Energy, the guy who invented Energy Star, said “If you show them infrared pictures of the problems in their home, they are five times more likely to want you to fix the problem that day!” With a few images and a simple explanation of the science, the homeowners had no issues adding spray foaming the rim joist and a package for insulation removal and advanced air sealing to the project. This increased the job by $5,000, transforming it from a small job into a much more sizable, profitable and beneficial one.

The proper equipment and a willingness to spend a few minutes talking customers through what they see is a proven path for upselling in real time, leading to more work for you and better results for them. And since your success is how we measure our success, IDI makes it a priority to carry high-quality infrared cameras and other vital diagnostic tools that can help grow your projects in real time.

Looking for advice on specific equipment or insulation? Reach out to us at IDI for the information you need.