Pole Barn Insulation

We’re Here For Your Pole Barn Insulation Needs

With over 45 years of experience in insulation, our team of insulation specialists brings innovation and research to the agricultural construction market for post-frame insulation. We serve as the energy solution experts offering our product line in over 60 locations to deliver all types of insulation and accessories with technical expertise for poultry house insulation, equine barn insulation, and more. The right pole barn insulation product and application can improve the use and comfort levels inside of your building. Let us work for you to provide all types of barn insulation (including foam), ceiling film, poly and so much more. Our branches have dedicated drivers and trucks to deliver direct to your jobsite or your warehouse.

RETROFIT AND NEW INSULATION SYSTEMS FOR YOUR BUILDING

Throughout the life of a post-frame building, the use of the building can change several times. This can make it difficult to determine how to properly insulate your building based on its uses. The good news is that insulation can easily be retro-fitted to suit the new use of the post-frame building. Because you don’t want to be spending money on each change and detail, there are several types of post-frame insulation that improve overall performance while emphasizing use. IDI provides industry-leading products that include several types of insulation systems and solutions. Most of these products can be used for both new and pole barn insulation retrofit projects.

Benefits of the right insulation system for your pole barn

Pole barn insulation will keep your building running for the long term. With an airtight seal, you won’t have to worry about the buildup of mold, dust and other particles.

Condensation Prevention

Internal Temperature Control

Protecting Assets or Animals

Extending the Life of Your Buildings

Our process for post-frame insulation

Today there are several different ways to insulate your post-frame building or pole barn. Here are some of the primary products that IDI uses to get the most efficient results:

Reflective Insulation

This can be a thin fiberglass core material or a bubble wrap type product. Either one is ideal for adding additional structural support or can be used as a retrofit.

Learn More- This product is typically installed between the wooden purlin/girts and the metal roof or wall panels.

- A reflective air space between the product and the roof or wall panels is required for the product to be effective.

- Will reduce radiant heat gain.

- Ventilation of the building at the eaves and ridge is necessary.

Spray Foam Pole Barn Insulation

Spray foam pole barn insulation can be installed in new or existing buildings. IDI always recommends that a spray foam contractor be hired to perform this work for safety purposes.

Learn More- Closed cell vs. Open cell: Both products can be used, but it depends on your climate and the contents of your structure.

- Spraying directly to the inside of the metal panels can be done, but make sure that the surface is cleaned of all oil and debris.

- Make sure that the panel is 26 gauge or thicker.

- Spray foam applied to thin metal may cause the metal to buckle or oil-can.

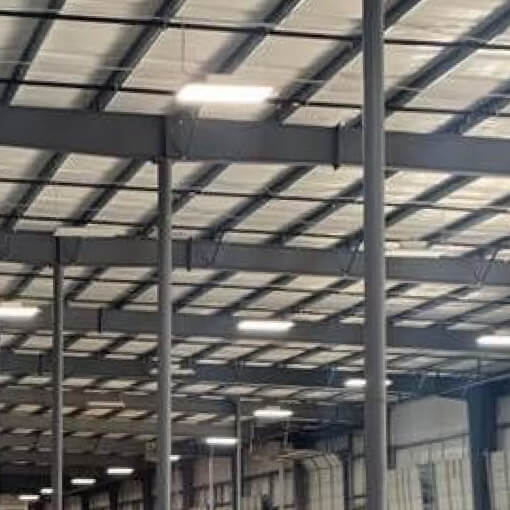

Metal Building Fiberglass Insulation

Fiberglass post-frame insulation can be used on a variety of metal buildings. This form of insulation adds an extra layer for sound protection and increased internal temperature.

Learn More- Due to the thickness of the fiberglass, we do not recommend that anything greater than 2” be installed between the wooden girts/purlins and wall/roof panels.

- It is common to install metal building type insulation on the walls. Typically insulation will be the same thickness (or slightly greater than) as the wood post thickness. The insulation will fill the cavity between the wood posts.

Blown-in Insulation

Blown-in insulation is also fairly common in post-frame buildings. The application is typically installed in the roof and is applied at the bottom chord of the trusses over different substrates.

Learn More- Metal liner substrate is installed under the bottom chord of the trusses. The insulation is then blown in over the top of the metal liner.

- Heavy-duty fabric facing. The most common would be the WMP-50 product. The WMP-50 would be installed under the bottom chord of the trusses and the insulation would then be blown in on top of the facing.

- With each system, it’s very important to provide good eave and ridge ventilation.

Common Questions About Pole Barn Insulation

At IDI, we work for you. That means we’re here to answer all your questions and help you get more leads. Here are some frequently asked questions about pole barn insulation and solutions from IDI Distributors:

Condensation! We see it often as heat increases throughout the day and creates condensation in the building. Many times building owners believe that there is a leak. This is why good ventilation and the eaves and the ridge are so important.

It is very easy. Insulation can be easily installed on the walls and to the roof.

With new construction, the building erector will install the insulation (unless it is blown-in). For retrofit, we always recommend that you hire an insulation contractor.