Operating a business can be demanding and stressful, even when everything is going as planned. Unfortunately, workplace injuries happen, but they are not something you want to be unprepared for. On a normal day your team deals with everything from lifting heavy items, to climbing in and out of a truck (sometimes in wet or icy conditions), from working on stilts, ladders, or scaffolding, to handling chemicals, high pressure equipment, and the list goes on. The question is, do you have a plan to respond to workplace injuries and does everyone know the procedures to ensure they are handled properly?

The first step with any workplace incident is taking care of the injured person(s) needs. Medical attention should be provided as soon as possible. Having a first aid kit at your shop and in company vehicles is critical. So is making sure they are fully stocked. As part of your monthly routine, is someone in charge of making sure the kits are replenished and ready to be used if needed? Medical or injury events often derail operations for a day, maybe even a week. In addition to checking first aid kits monthly, it’s a good policy to have a team member assigned to restock the kit every time there is an injury.

Make sure that after any incident, your team knows the area is safe before investigating, rescuing, or resuming work. They also need to understand any time frames required for reporting severe injuries, illnesses, or accidents. Reporting for companies with less than 10 employees is less stringent than those with more. As stated on the OSHA (Occupational Safety and Health Administration) website, “If your company had 10 or fewer employees at all times during the last calendar year, you do not need to keep OSHA injury and illness records unless OSHA or the Bureau of Labor Statistics informs you in writing that you must keep records under § 1904.41 or § 1904.42. However, as required by § 1904.39, all employers covered by the OSH Act must report to OSHA any work-related incident that results in a fatality, the in-patient hospitalization of one or more employees, an employee amputation, or an employee loss of an eye.”

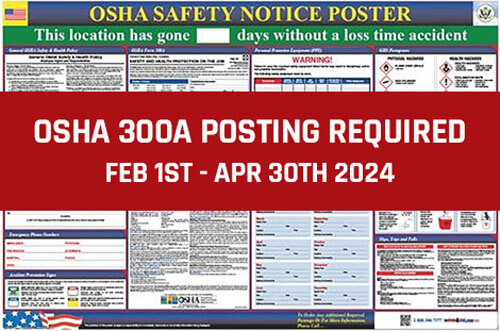

With the above statement from the OSHA website, keep in mind that your number of employees is based on your peak employment for the year. Even if you only had ten employees for one project during the year, you would be considered as having ten. For reporting, forms 300 & 300A are used. Form 300 is a comprehensive record of workplace injuries or illnesses kept for reference and not for public information. It is, however, filed according to OSHA rules. OSHA Form 300A summarizes form 300 but removes all personal information. As for posting, Companies must post the previous year’s Form 300A at your workplace, in a common area where notices to employees are usually kept from February 1 to April 30. Even if you have no recordable events last year, you can just enter “0” in each field, but you are still required to post.

When investigating an incident, it’s important to determine if required procedures were followed. If not, try to find out why not, and how to ensure they are followed in the future. Record what happened without placing any blame until after the investigation is completed. This helps ensure you get accurate information. If OSHA comes to investigate your incident, stay courteous and don’t hide information. It’s a good idea not to share information unless they request it. That said, be honest and don’t share more than you’re asked to.

Make sure to keep good records of the incident. Take witness statements, photos, and include any documentation that would be helpful in case you are investigated by OSHA.

After the investigation, you can decide if new policies or procedures need to be put in place to prevent this type of incident in the future. Regular safety trainings are the best way to share any policy or procedure updates to all employees. Many contractors already have a weekly or monthly meeting with their install crews, which is a great time to include safety training.

No one wants to have to contend with a workplace accident, but unfortunately, they do happen. Make sure your company and employees are safety trained. Everyone should know the location of all safety related resources including first aid kits, SDS sheets, fire extinguishers, etc. Having a good plan that is understood by everyone can make a world of difference when it comes to workplace injuries.

If you have questions about safety training, SDS’s, or best practices with any of the products we carry, simply reach out to your local branch, or contact anyone at IDI, where we look forward to earning your business every day.